1. What is the function of a guard column? What makes a good guard column? What are the different guard column designs? How do I install a guard column?

The guard column is installed between the injector and the analytical column and is designed to increase the lifetime of an analytical column by protecting the analytical column from unwanted materials, such as (1) highly retained or (2) irreversibly retained compounds and (3) particulate matter.

-

Examples of highly retained compounds are fatty acids or oils when operating under reversed phase conditions (e.g., C18 column and methanol/water or acetonitrile/water mobile phase) where the retention factors of the fatty acids are infinite at the strongest mobile phase condition.

-

Proteins can be examples of irreversibly retained compounds (in reversed phase HPLC) when operating under conditions in which proteins are not soluble in the mobile phase. This can happen when not all protein has been removed during an extraction before the sample is injected.

-

Particulate matter may be introduced by the sample, if not appropriately filtered before injection. Particulates may also be shed by system components such as seals in the pump or injector.

What makes a good guard column?

-

Since the role of a guard column is to prevent fouling of the analytical column, the guard column should be considerably less expensive than the analytical column it protects.

-

To simplify method development the guard column should contain the same packing material as the analytical column.

a. A larger particle size is acceptable as long as the packing material has the same chemical characteristics as the packing in the analytical column.

b. The use of guard columns filled with large particle size pellicular packings used to be popular. Pellicular guard columns are relatively cheap and are effective in protecting the analytical column from particulate matter, but their low retentive capacity made them less suitable to protect the column from highly retentive sample components.

-

To minimize the backpressure in the system, the length of the guard column should be as short as possible, while being long enough not to cause breakthrough of strongly retained solutes to the analytical column.

-

To minimize the backpressure in the system, the diameter of the guard column should be the same as the ID of the analytical column.

a. Since the flow rate of the analysis is determined by the requirements of the separation on the analytical column, a guard column with a smaller ID would cause extra back pressure over a guard column that has the same ID as the analytical column.

b. This consideration is less important the shorter the length of the guard column (1 - 1.5 cm). Since back pressure is proportional to ID2, a 1.5 cm × 3.2 mm ID guard column generates (4.6/3.2)2 ~ 2 times the back pressure of a 1.5 cm × 4.6 mm ID guard column.

-

The top frit of the guard column has usually the same pore size as the frit on top of the analytical column, although the pore size can be larger if the guard column contains a larger particle size packing material.

a. The top frit should be small enough to prevent packing particles to block the frit when flow is momentarily interrupted during injection or when other sudden changes in back pressure occur.

b. The top frit should be as large as possible to prevent frequent clogging from particulates derived from the sample or from system components.

c. Since the top frit of the guard column is the most likely frit to get clogged during continued operation, it is helpful if the frit can be cleaned or replaced with relative ease.

What are the different guard column designs?

Guard columns are available either as small replaceable columns or as guard cartridges that are easily inserted into a hand-tight guard column holder. DC guard columns can be directly connected to the analytical column without tubing between the two columns. A male-type outlet endfitting on the guard column enables the direct connection to the screw-type endfitting of the analytical column.

How do I install a guard column?

Installing a guard column is performed the same way as a primary column is installed, using stainless steel or PEEK tubing and fittings.

2. Is it always necessary to use a guard column with a TSKgel® analytical column?

A guard column is generally recommended because it protects the analytical column from a major contamination of the HPLC, e.g. pump seal failure. It also protects against inadvertent overloading of the column because a guard column is both a particulate AND molecular filter. However, if the mobile phase and sample are filtered to 0.22- 0.45 micron a guard column may not be necessary. The user still, however, exposes the column to the potential contamination from the HPLC system.

3. How do I assemble a stainless steel guard column kit?

Watch the instructional video, or follow these instructions:

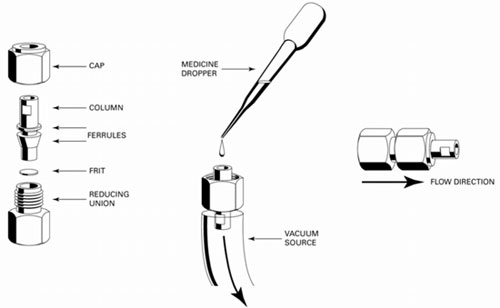

TSKgel® guard columns are shipped partially assembled. The first step in assembling a guard column is to set the ferrules onto the column. Place the column assembly on the table with the column facing up, as shown in the figure on the left below. Using wrenches, tighten the cap onto the reducing union by making approximately 1/2 turn. This should set the ferrules onto the column tube. Separate the cap and the column from the reducing union. Take the frit out of the reducing union and place both on the bench.

-

Fit the cap and the column into a laboratory clamp.

-

Attach tubing from an aspirator or other gentle vacuum source to the column and apply suction.

-

Resuspend the Guardgel in its container by adding about 10mL of the appropriate shipping solvent.

-

Pipet the slurry into the column using a medicine dropper or pipet.

-

Continue adding gel until the surface of the gel bed is flush with the top of the column.

-

Remove excess packing with a spatula. Make sure that no packing is left on the ferrules.

-

Disconnect the vacuum source.

-

Place the frit and the reducing union on top of the packed guard column. Tighten with a wrench.

-

Connect the guard column (at the reducing union side!) to the injector of your HPLC or LC system following the procedure described for the separation column in the Instruction Manual.

-

Start the pump at a low flow rate (0.5 mL/min) and slowly increase to 1 mL/min.

-

Connect the guard column to the analytical separation column after sufficient solvent has exited to expel all air from the guard column.

4. How can you tell when it is time to change your guard column?

Unfortunately guard columns are not like light bulbs that burn out when it is time to change them. It is best to get into a routine of changing guard columns on a regular basis like you would a water filter. Tosoh recommends replacing guard cartridges after every 30 to 40 injections although this frequency can vary depending on (1) the mode of chromatography, (2) the chemical nature of the sample, (3) the cleanliness of the sample in terms of particulate matter or the presence of highly retained components, the volume injected, etc.

Signs that might indicate a need to change the guard column are higher than usual back pressure, peak broadening, changes in selectivity or changes in retention time. To determine the cause of the change in efficiency, selectivity, retention or pressure, it is recommended to remove the guard column and check the performance of the analytical column under the manufacturer’s QC conditions. Of course, one needs to always keep in mind that a malfunction of the HPLC system can also result in higher or lower than usual pressure, changes in retention and selectivity, and loss in column efficiency.